Technological, beautiful, easy to use, but also more and more careful to the noise and air quality: always more hoods take care of the kitchen environment.

by Simona Preda

To better understand technology, design, materials, energy saving, we asked information to some companies. Here is what they told us Valentina Rosmino, Candy built-in trade marketing manager in Italy, Francesco Boromei, chief marketing officer of Elica; Riccardo Remedi, commercial director of Faber and Andrea Poser, head of marketing of Falmec.

What consumers want

«Consumers often give importance to the brand and trust it for its reliability,” begins Francesco Boromei of Elica. «The most requested features are technology, innovation, performance, design and comfort of use.» Valentina Rosmino of Candy agrees: «a strong appeal combined with functionality, product extraction power and smart technology, are among the most requested characteristics by consumers.»

«Surely there are two aspects that dominate consumer interest for a hood: design and performance,» Riccardo Remedi of Faber explains. «Design does not need to be necessarily something visible. Products, in fact, may have a minimal look, linear or even be concealed. In any case, the performance of the product must meet the minimum requirements for a hood, with a good level of air suction in cubic meters and an acceptable noise level.»

Andrea Poser of Falmec adds that «we are aware that in addition to aesthetic factors, what is required by customers is especially efficiency, reliability and ease of use. Above all the odors aspiration is one of the most common expectations, with the possibility that they can be eliminated even in the case of filtering hoods, and of course the quiet operation, because the noise is perceived as very annoying.»

The importance of design

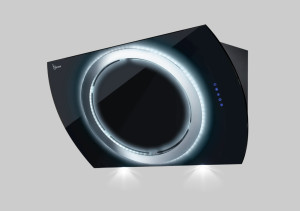

The opinion is unanimous and all the companies are not neglect this aspect. «Design is a key factor for the consumer,» Valentina Rosmino of Candy explains, «and it is for this reason that our hoods from element characterized mainly by the extraction function, become today a real piece of furniture.»

Riccardo Remedi of Faber points out that « design has a more dominant role for the hood than for other appliances, because it has a central and visible position in a kitchen. The hood appearance must be adapted to the design of the kitchen: in a minimal kitchen even the hood will have a minimalist design. That is why we propose a wide range of products, specifically designed to perfectly fit into any environment. In addition, working closely with the manufacturers of kitchens, we always keep up with the latest trends.»

«Design is very important, also because the consumer has evolved very much and so he is more careful in assessing the various proposals,» Andrea Poser of Falmec explains, «although in recent years there has been a tendency to integrate the hood inside the wall cabinets or the ceiling. Obviously in these cases the product requires a minimal design and functional solutions that make the suction effective, with use of the hood as simple as possible.»

Even Francesco Boromei of Elica agrees: «design is one of the most important parameters and the trend is to integrate the spaces with the hood which also has a furniture function. Our range is very wide and we drive the sector; in particular in the high lines we propose products with a special design. It is a careful study of the lights, shapes, materials and hints come from different sectors, such as the motoring.»

Materials: steel and glass

Riccardo Remedi of Faber points out that «still today glass and steel are the dominant materials in the hood. However, attempts are made to introduce synthetic materials such as Corian and polycarbonate, which allow a good versatility in terms of shapes and colors.» «Glass and steel are the most used materials,» Francesco Boromei of Elica adds, « but we also propose colorful products, designed to coordinate and integrate with the kitchen, making the hood more and more a furniture element.»

«We mainly use AISI 304 steel,» Andrea Poser of Falmec explains, «which differs from the one usually employed. It is in fact a much higher quality steel. This is accompanied by the glass, which is also a noble and versatile material, used in various shapes, transparent, painted, oxidized, screen-printed.»

«Candy is always careful to details and the use of high quality materials,» Valentina Rosmino of Candy highlights. «The aluminum panels, the tempered glasses and the carbon filters are just a few examples of materials that make our hoods elegant and at the same time able to provide comfort and durability.»

Benefits of perimeter extraction

«A very common technique is the perimeter extraction,» Riccardo Remedi of Faber says. «At the bottom of the hood there is a panel made of steel or glass, so the suction is through the perimeter hole positioned there. This technique allows excellent levels of suction capacity, identified with the Venturi effect, that is, the acceleration of the air in the perimeter hole, which is then easily expelled, while also allowing a reduction of noise and an elegant hood aesthetics.»

Valentina Rosmino of Candy emphasizes that «for some models in the range the perimeter filter has been introduced, which gives more elegance to the hood hiding the filters. In this case the effectiveness of the air cleaning is improved, because fumes and vapors are conducted along the perimeter of the hood; thus their speed slows down and filtering is also more accurate.»

The air quality

It is essential that the hood clean and purify the air from smoke and cooking odors. So filters are important but also some technologies specifically developed. «The most important thing to save the air quality is the hood ability to recycle,» Riccardo Remedi of Faber explains. «The extraction models must be able to provide a complete change of the air at least 10 times per hour in a kitchen. When the air does not come outside, but is replaced in the environment, it is fundamental the use of high efficiency carbon filters: this is the case of the Faber HFH filter, which captures odor up to 95% and is washable in the dishwasher and therefore reusable.»

Francesco Boromei of Elica explains that «to improve the air quality, we have developed a new polyurethane filter, protected by an international patent, which allows a high filtering capacity and a superior filtration efficiency. It is A class certified by the new European Union energy label.»

«Often the indoor air is even more polluted than the outdoor one,» noted Andrea Poser of Falmec. «That is why, if the hood is installed in the filter version, we recommend our E.ion models that, thanks to their special technology that uses a system of controlled bipolar ionization, are able to improve the air quality in the kitchen, reducing odors up to 95%, as well as viruses, bacteria, mites, pollens, cooking fumes and cigarette smoke, and others. In addition, these hoods are equipped with a sensor that constantly analyzes the degree of quality of the indoor air; represented by an icon depicting a leaf. Its color varies on the basis of the air purity or pollution degree: green if the quality is good and gradually becomes yellow when it detects an increase of present volatile gases.»

Valentina Rosmino of Candy explains that “many of the models in the range are equipped with the Clean Air function, an intelligent mode of operation that switch on the hood at minimum speed for 10 minutes every hour, ensuring an effective air exchange. The timer function allows to set the automatic shutdown of the hood in the absence of the user, providing an effective air exchange without limiting comfort and freedom.»

Down with the noise

A good hood must be efficient in the aspiration, aesthetically pleasing, but also produce little noise; here are some examples of technologies used for this purpose.

«Our Silence collection uses the NRS (Noise Reduction System) technology,» Andrea Poser of Falmec underlines, «which combines the use of specific sound-absorbing materials with in-depth studies on fluid dynamics. The result is a minimization of turbulence within the product and noise minimized, to be almost imperceptible, without compromising the effectiveness of the hood.»

Riccardo Remedi of Faber explains that «we offer a unique system in the hoods world, with an active noise reduction, combining the passive reduction through the use of sound-absorbing materials and the use of Sil-K ACT technology, able to break down noise pollution through the sound cancellation. Faber has been able to apply for the first time in an appliance this sophisticated system, already used in aeronautical and automotive, which is called Active Noise. After recording the sound directly from the source, Sil-K ACT analyzes the sound wave and creates a contrary one, which erases the original, thus eliminating any acoustic perception, with a reduction in emissions of 13 decibels less than an analogous model.»

Francesco Boromei of Elica explains that «the hoods equipped with the Elica Deep Silence (EDS3) system are very quiet. The technology used allows a functionality extremely quiet, even imperceptible at low speeds, with a reduction of environmental noise by more than 35% compared to traditional hoods, without compromising the performance of extraction.»

«Candy hoods ensure a high quality filtering performance and a low noise level,” Valentina Rosmino of Candy says. «The technology used allows to drop to only 31 decibels of noise, which means almost do not hear the hood while it is running.»

Energy saving with the brushless motor

«We’re aligning to the 2015 energy label,” says Riccardo Remedi of Faber, «so all of our products will be equipped with components that will allow to achieve the best energy class by product type, with the possibility to get up Class A ++, working on motors, speakers and lighting. In many of our products we already adopt technologies such as the brushless motor, the quietest on the market and with stable performance in any condition of use, which guarantees a considerable energy saving while maintaining an high efficiency of suction. In addition, from long time we have using for the illumination the LEDlight technology, which ensures optimum light distribution in the cooking area and a pleasant and relaxing intensity (4100 ° K), with a power consumption of only 2 W .»

Andrea Poser of Falmec agrees «Almost all of our products use LED lighting, that ensures low energy consumption and long life. At this, in a short time, we will add a motor with high efficiency and low power consumption, so as to ensure maximum energy classes.»

Commercial channels

«Our hoods are sold in the channel of the furniture, because it is the most suitable for this type of product that needs to be installed,» Francesco Boromei of Elica explains. «Our business in Italy is mainly with the manufacturers of kitchens,» Riccardo Remedi of Faber agrees, «that represent our most important channel and with whom we want to continue to have a very close cooperation relationship, trying to follow with them design trends in the domestic furniture. In the large distribution we are present, with extremely prudent choices: we offer to this channel a dedicated range, different from that of the kitchen manufacturers.»

Andrea Poser of Falmec explains that «our products are sold by the manufacturers of kitchens or through regional distributors; their client is always the kitchen retailer. We are not present in the electronics large distribution, because we believe that with products like ours, positioned in the upper-medium segment of the market, the professionalism and competence of kitchen retailers is crucial to better promote them and to inform consumers about the characteristics that differentiate them from the rest of the market.»

A different choice is made by Candy, as Valentina Rosmino explains: «The sales channels that we use today for our hoods are: the electronical retail, large distribution of furniture, manufacturers of kitchens and distributors channel throughout the country. In this way we have created a widespread coverage of the whole national territory and an effective brand exhibition and enhancement.»

Lorenzo Baraldi, CEO of Baraldi Hoods: “The situation remains difficult on some traditional channels and the advent massive for our products of online sales is repositioning the whole business process. We believe more and more in all instruments related to the Internet world, from social to large international sale products, so is the supply of new models that investments of communication will be more and more associated with this field. To date, the absolute values are still not as important, but the level of growth of this channel from year to year is always more surprising. This also involves issues related to product development. At one time, for example, you had to wait many months before we have answers from the market to understand the success of a new model of innovative features or finishes. Today in a few weeks you can understand the potential and change in the running many details”.

Lorenzo Baraldi, CEO of Baraldi Hoods: “The situation remains difficult on some traditional channels and the advent massive for our products of online sales is repositioning the whole business process. We believe more and more in all instruments related to the Internet world, from social to large international sale products, so is the supply of new models that investments of communication will be more and more associated with this field. To date, the absolute values are still not as important, but the level of growth of this channel from year to year is always more surprising. This also involves issues related to product development. At one time, for example, you had to wait many months before we have answers from the market to understand the success of a new model of innovative features or finishes. Today in a few weeks you can understand the potential and change in the running many details”.